TESTS ON LAMINATED GLASS FOR RAILWAY WINDSHIELDS

(Pubbl. 16/04/2025)Trenitalia's technical specifications require testing the laminated glass of driver's cabins with a test that ensures their safety upon impact. This involves verifying the glass's resistance to the piercing action of an object propelled at high speed against it using a compressed air cannon.

COMPRESSED AIR CANNON

How is the laboratory test performed?

This test is carried out in accordance with the requirements of the technical specification FS308074 "Safety Glass for Driver's Cabins of Railway Rolling Stock," paragraph 6.2.10 "Impact Resistance Test."

At the client's discretion, the test can be performed on specimens with laminated glass either with or without the application of an anti-shatter film.

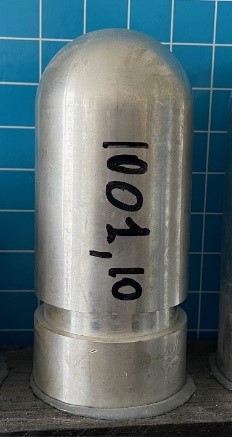

The test examines two samples at two different temperatures (20 °C and 0 °C). A projectile weighing 1000 g and having dimensions defined by the same technical specification is fired against each sample.

1 KG PROJECTILE

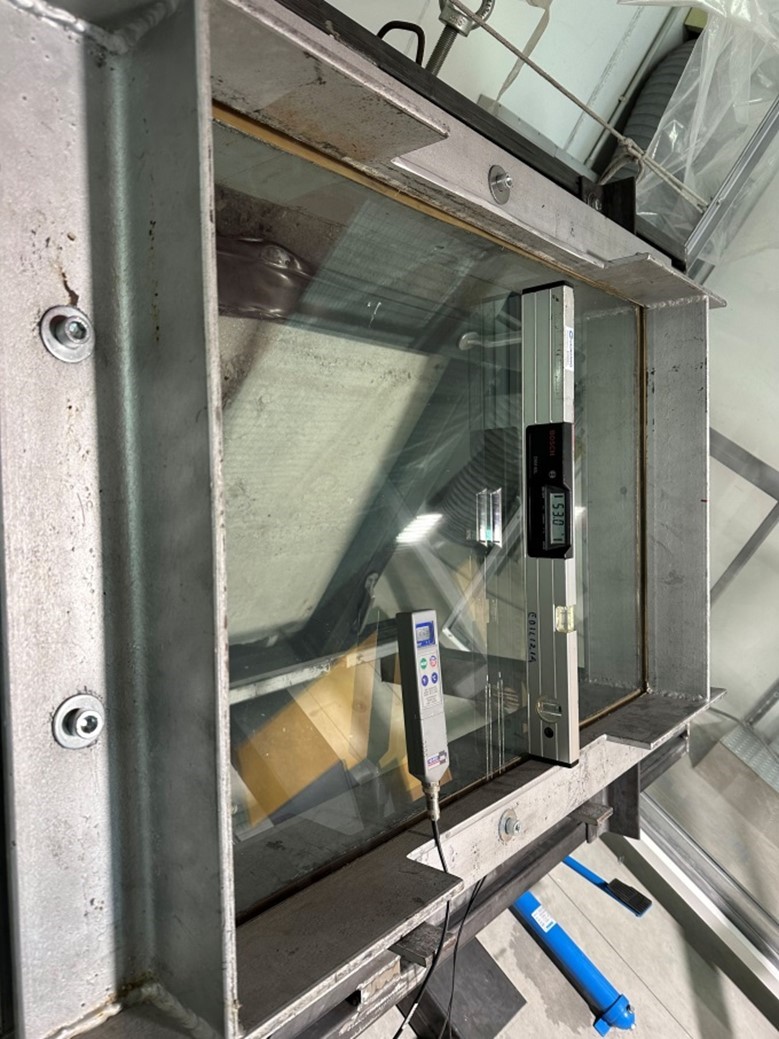

MONITORING OF INCLINATION AND TEMPERATURE

Test Passed?

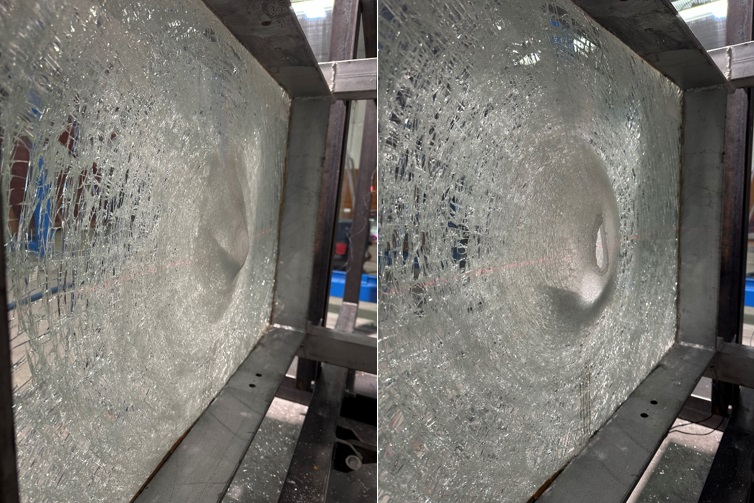

The ballistic test is considered passed if the laminated glass specimens without the anti-shatter film, while being damaged, are not penetrated by the projectile.

Similarly, for the laminated glass specimens with the anti-shatter film, the test is considered passed if they are not penetrated by the projectile and if the anti-shatter film shows no breakage that could be associated with the possible projection of shards from the inner glass layer.

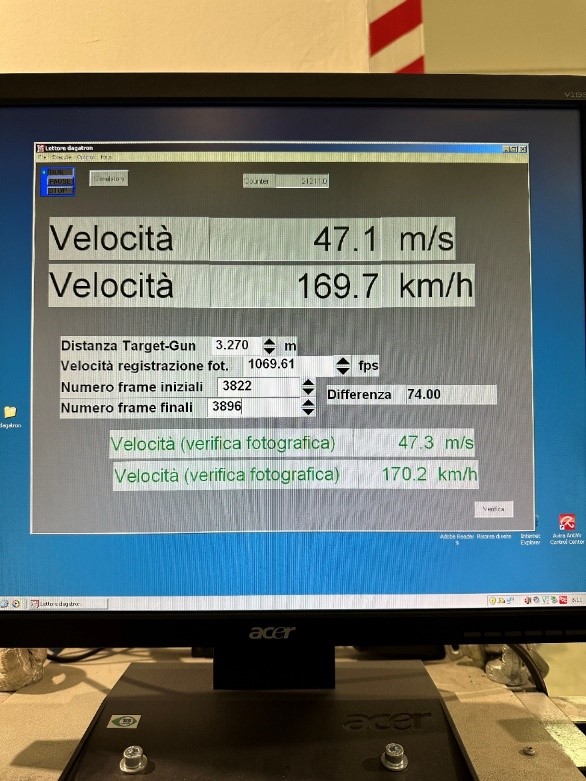

MONITORING OF THE VELOCITY AFTER FIRING

REAR PHOTOGRAPHS OF THE SAMPLE AFTER IMPACT WITH COMPLIANT AND NON-COMPLIANT RESULTS

Equipment Used for the Test:

- Climatic chamber

- Thermo-hygrometer

- Compressed air cannon for ballistic tests

- 4 projectiles manufactured according to the technical specification

- Digital pressure gauge

- Velocity detector

- Multimeter

- Steel frame for specimen support

- A reinforced concrete containment trench

Discover all our activities in the railway sector

Over the years, Istituto Giordano has developed, thanks to its multidisciplinary approach, a range of instruments and technical expertise capable of supporting manufacturers of railway components and, more broadly, the transport sector. We specialize in conducting “special” tests that require custom setups for specific standards or the technical specifications of the client.

To learn more about all our activities in the railway sector, please visit the dedicated page.

Do you need more information about our services?

Do you need more information about our services?