Sand & Dust Test: sand and dust resistance tests under MIL-STD 810 and RTCA DO-160

(Pubbl. 30/01/2025)Tag:

safety

At the testing laboratory for avionics and military components at Istituto Giordano's Pomezia site, Sand and Dust tests can be performed under the following standards:

✔ Particle size: < 150 μm

✔ Simulated effects:

✔ Particle size: 150 - 850 μm

✔ Simulated effects:

The objective is to reproduce critical operational scenarios and evaluate the tested components' structural integrity, functionality, and durability.

- MIL-STD 810 Method 510 (Procedure I and II)

- RTCA DO-160 Section 12

Types of evidence: Dust and Sand

The infiltration of particles into devices can impair their functionality, causing structural or electrical damage. In order to check their resistance, the tests fall into two main categories:- Test Dust (Procedure I - Dust)

✔ Particle size: < 150 μm

✔ Simulated effects:

- Obstruction of openings and cracks

- Penetration into joints, bearings and critical components

- Effectiveness of filtering systems

- Possible damage to electronic circuits and exposed surfaces

- Test Sand (Procedure II - Sand)

✔ Particle size: 150 - 850 μm

✔ Simulated effects:

- Abrasion of external surfaces (erosion)

- Clogging of air intakes and filters

- Mechanical and electrical functional losses

- Reliability testing under extreme operating conditions

Test conditions and test parameters

Tests are performed in controlled environments, where temperature, wind speed and particle concentration are adjustable to simulate real-world conditions. Although the tests are conducted according to MIL-STD 810 and RTCA DO-160 standards, the parameters can be customised according to specific customer requirements.The objective is to reproduce critical operational scenarios and evaluate the tested components' structural integrity, functionality, and durability.

How are the tests performed?

Sand and Dust tests are performed with the following parameters:- Temperature: 49°C (adjustable up to 71°C on request)

- Wind speed: 18 m/s (up to 29 m/s on request)

- Dust concentration:

- MIL-STD 810: 10,6 ± 7 g/m³

- RTCA DO-160: 3,5 – 8,8 g/m³

- Sand concentration: 0,18 – 2,2 g/m

- Test materials:

- Certified powder (≥98% SiO₂, particles <150 μm)

- Certified sand (≥98% SiO₂, particles 150-850 μm)

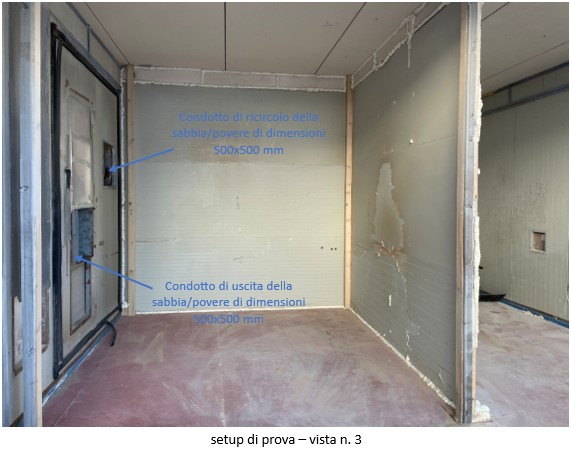

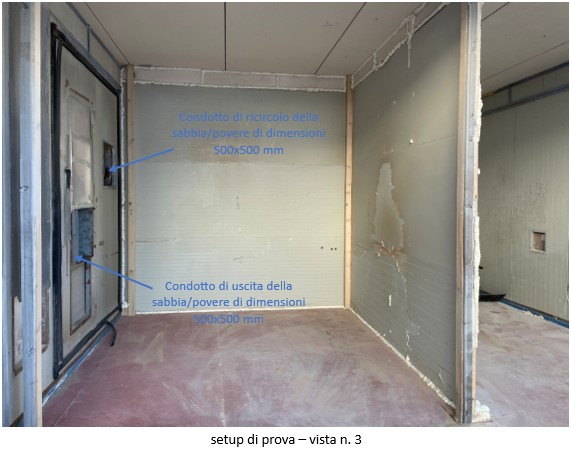

- Small room: 1500x2000x2000 mm (ideal for avionics, electronics and sensors)

- Large room: 5000x6000x3000h mm (suitable for military vehicles, shelters and large systems)

- Room temperature and humidity (via data logger)

- Thermal stabilisation and internal temperature of the sample (via T-type probes)

- Wind speed (measured with an anemometer to ensure stable values without turbulence)

Do you need more information about our services?

Do you need more information about our services?